In which I keep track of my progress building the Elecraft K2, KPA100, and other kits ...

Wednesday, December 29, 2010

Sunday, December 26, 2010

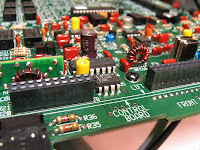

Lots of KPA100 Capacitors

Having finally gotten through the large number of capacitors to be stuffed on page 17, I thought it was time for a posting with some pictures.

The other instruction for the bottom-mounted capacitors concerned minimizing the amount solder used on the top of the board for these caps. This was necessary because the top-mounted relays all sit directly on top of the solder pads and have a very small, but consistent, clearance above the board. This was easy to do, and there were no problems later on with stuffing the relays.

Finally, I was unable to get RFC9 locally. I wrote to Elecraft's part line this past Monday, and had the replacement RFC in hand in Thursday morning's mail(!). Another great job by Elecraft staff and, for a change, by the USPS.

Taking a break from part-stuffing and am winding inductors, so they will be ready to stuff when I get there in the instructions.

Saturday, December 18, 2010

RFC9

I stuffed most of the resistors and was getting a start on the RFCs. I fiddled with the leads for RFC9, trying to get it to sit flush against the board, long enough to succeed in breaking off one of the leads. It was then that I had a look at the e-mail reflector, did a search on "KPA100 RFC9", and immediately got a hit. Someone was wondering about the same thing and was referred to this document. Well, I wish a reference to this document was included in the KPA100 instructions. It seems that a number of years ago Elecraft stopped using sub-miniature RFCs in favor of miniature RFCs; however, the hole spacing on the KPA100 board fit the sub-miniature parts.

One other construction note: I stuffed D1 to D8 on the bottom of the board, but the instructions did not say whether these are to be soldered on the bottom or top of the board. I looked back at the few bottom-mounted parts I had previously stuffed and, in each case, the instructions were explicit about soldering on the top. Since nothing was said here, I decided to assume that this meant "solder on the bottom", which I did.

Friday, December 17, 2010

Getting The KPA100 Underway

There aren't many resistors in this kit, but there are loads of capacitors. They are sorted out in the middle tray in the back, with the small lots in the envelopes to the right. As you can see in the right foreground, there will be quite a few inductors to be wound. All the relays, hardware (nuts, screws, washers, etc.), wire, speaker, fan, and so forth, are sorted out into ziplock bags and are back in the box, awaiting their turn.

Tuesday, November 30, 2010

W1 Completed and On-line

There were no glitches during construction. The only really time-consuming part of the project was winding T1, which I did while waiting for the missing caps to show up in the mail. I also put together a serial cable to try out the software that can be downloaded from the Elecraft web site. At first it seemed like the software didn't work. However, testing using HyperTerm on my PC revealed that the serial cable was picking up RF from the K2; winding the cable several times through a large toroid solved the problem, and the software worked great.

By the way, running 10 watts into dipoles and my 80/40 meter end-fed random antenna resulted in 165 contacts in the CQWW contest, including contacts in Australia and Japan on 20 meters (and thanks to both ops for hanging in there with me to get my call sign correctly)! Still can't decide whether I need additional filters; I'll see how the contest goes next February, I guess.

Tuesday, November 16, 2010

Elecraft W1 Wattmeter/SWR Bridge

My Elecraft W1 kit arrived in the mail yesterday. It weighed 1 pound and was therefore too heavy to be shipped USPS First Class. However, another shipping option was USPS Priority Mail, which arrived here as fast as First Class and was way cheaper than UPS.

I inventoried the kit upon arrival and it was unfortunately missing all 8 .01 uF capacitors. I wrote to Elecraft's parts e-mail, got an immediate response, and just received an automated e-mail telling me that the parts were just shipped USPS First Class ... should be here Thursday.

Monday, October 18, 2010

N-gen

I ordered the N-gen kit last Thursday and it arrived in USPS mail today. It was a very simple kit, with very few parts. I guess I still don't understand Elecraft's pricing on this (a tiny fraction of the parts in the K2 at about 8% of the cost), but it was fun to put together and will be a nice tool in my shack.

The next step will be to align all the filters using Spectrogram and the very detailed procedure described in this document at the late N0SS's archived web site.

Friday, October 8, 2010

Success!

First contact with the new rig: on 20 meters with UA6YH (Alex), east of the Black Sea. My report was 559 ... very satisfying, especially for 10 watts and a not very high dipole!

Thursday, October 7, 2010

"This completes assembly of your K2"

Well, "two or three hours" was a bit optimistic! It actually took quite a while to get through the last four transformers. I was being extra careful about getting the spacing right. T4 turned out to be fairly brutal; getting those two "link" windings into their respective soldering pads right next to T3 was nearly impossible for the size of my fingers.

|

However, by late afternoon, I completed assembly of the RF board (whew!!) and plugged the three boards together and mounted it all in the case, ready for Integration Test 3 and alignment. |

|

I ran the N6KR method for setting the 4 MHz reference oscillator, which worked really well, and ran through the receiver and transmitter alignment steps a couple of times (last night when I was too darned tired, and then again today when I was fresh and actually read the fine print!!) ... and depicted is the result ... Elecraft K2 S/N 6982. |

Actually, I did as much of the alignment as I could. I don't own a noise or signal generator and 10 and 12 meters were so dead there was nothing for me to use to peak the band pass filters. Also, I don't own a dummy load and don't have antennas for all the bands either, so I couldn't peak all the band pass filters by the transmit method either. I plan to build the KPA100 (100 watt module) next (heh ... stay tuned for more blog posts later this year) and will get a dummy load as part of that project. I also will probably get Elecraft's N-GEN noise generator (although I think they charge too much for it!). With noise generator and dummy load in hand, I will be able to complete alignment for the other bands.

Looking forward to getting on 20 meters tomorrow!! Right now ... very satisfied and very tired.

Tuesday, October 5, 2010

Home Stretch

I spent a couple of days just enjoying listening to 40 meters, and had to push myself to disassemble the K2! At that point, I decided to try to push through to finish assembly; there were only a few pages of RF board construction left to go to arrive at Integration Test 3. So, I've put in a lot more daily hours in the past few days and am now close to finishing the RF board.

|

Having documented my stuffing the first resistor on the Control Board, I thought I would amuse myself by also documenting stuffing the last resistor as well. R44 is the last small component to be stuffed, as well as the last component (except for the PA transistors) to be mounted on the bottom of the board. |

|

So, here's the whole RF board. All that remains to be mounted are 4 transformers, that I still need to wind, and the 2 PA transistors. Although it may not look like that many in the photograph, there were a lot of capacitors to be stuffed, many of which were the tiny ones that needed to have their leads formed to fit the solder pads. The last step in today's construction was really speeded by my having already wound L16 through L24 a week or so ago. |

Two or three more hours should see me through to Integration Test and Alignment 3.

Most of the way through page 70 ...

Friday, October 1, 2010

Integration Test 2

I completed RF Board Assembly, Part II. More on that in a moment but first some pics of recent interesting construction:

I didn't wait an extra day this time; I plugged the K2 in and turned it on as soon as I was done with assembly (actually, did take a break to eat some lunch). I'm very happy to report that all tests and alignment procedures were well within spec and totally successful. I've spent the past day happily listening to CW and SSB on 40 meters, tweaking set up parameters, tweaking filters, and getting to know the rig. I'm planning to take another couple of days off and then get back to construction.

Happy days!

Wednesday, September 29, 2010

Working on the bottom of the RF board

There are no pictures to post today, because there's not that much to see ... a modest number of parts distributed all across the bottom side of the RF board. It has turned out that installing parts on the bottom of the board has been the most difficult part of the project so far.

I found Elecraft's standard instruction to stuff some large number of components on bottom side of the board and then go and solder them all really didn't work for me. It almost seemed like I needed to customize in some fashion the installation of each component ... a bit of exaggeration, but I certainly did need to assess how I was going to install each component.

There were two main issues to deal with:

- Crowding on the top side of the board can make it necessary to solder a component on the bottom side of the board.

- You have to insure that no component is higher than the 2-D fasteners on the bottom of the board, so as to insure that nothing touches the bottom panel of the case when the K2 is assembled.

The instructions for installing components on the bottom board are prefaced with a brief paragraph that says basically "you may have to solder to the bottom of the board." In actuality, I soldered all the components in the last batch on page 59 on the bottom of the board, and I probably would have been better off soldering most of the components from the first batch on the bottom as well.

Soldering on the bottom was only really problematic for the monolithic capacitors, since they sit flush with the PC board and there is no lead exposed to solder to. For a lot of these, I ended up soldering them to the top of the board, even under some alarmingly crowded conditions. It turned out the solution was to put a 90° bend in the lead a very short distance away from the capacitor's body, trim the leads off, and then stuff them into their pads. The bend would expose the lead and then it was easy to solder. Depending on the size and location of the capacitor, it could then be bent upright or just left alone.

Thanks to Gary at Elecraft for helping me out with a couple of questions about bottom-side construction this week. In particular, he pointed out that C133's leads can be formed such that it sits lower than the nearby 2-D fastener and there is therefore no need to bend its body (which was a good thing, because there's really no place to bend it to!).

I took a day off from stuffing/soldering earlier in the week (I really needed a break!), and went ahead and wound L16 to L24 (on page 70). These will all now be waiting for me when I get to that stage of construction.

At the top of page 60 ...

Thursday, September 23, 2010

RF Board Top Front Completed

I've wound six inductors so far, 3 RFCs and 3 transformers (one of which, T6, had a bifilar winding). Having figured out how to strip and tin the winding wire, I actually find winding the inductors to be very soothing. It's time-consuming, but the time passes very pleasantly and calmly.

Nearing the bottom of page 58 ...

Tuesday, September 21, 2010

First two RFCs

So, I took a look at the K2 forum, and found a variety of tips, none of which seemed like the answer to me, until I came across one response which referred to this awesome video (does require RealPlayer). Using an 800° tip on my Weller, the "scraping" step wasn't even necessary; I just held the tip of the iron there and stuffed solder in until ... voilà ... it "wet out" (to quote the guy in the video), and then I could just slide the tip and the solder down to the end of the lead. As the guy said, "solder is cheap" and I kept just stuffing it in there. Anyway, this worked like a charm; installing the RFCs, etc., has moved from the "scary" column to the "piece of cake" column.

By the way, the first RFC to be installed is RFC14, in that little space next to the thermistor daughter board. It was really no problem fitting it in; there again was "plenty" of room.

Monday, September 20, 2010

Grounding the crystals

Today was "install crystals on the RF board" day, including the scary instructions for double-grounding X7 to X11.

|

First, though, here's a picture of the current state of RF board construction. You can see X7 to X11 at the extreme right hand side of the picture. |

After struggling to get the first ground wire on X7, I then went and checked the K2 forums to see what hints I could find. I wish I had looked there first! I used the following tips which various folks contributed to the forum, and it was pretty straightforward after that:

- This was probably the most helpful hint (and non-intuitive, considering the dire warnings about overheating the crystals!!), namely to use an 800° tip, instead of the 700° tip I've been using.

- I used some really fine grit sandpaper on the side of the crystal can (can't say it necessarily helped, but probably didn't hurt and may have helped).

- I then applied a little solder to the side of the can.

- I also had decided on my own to apply solder to each of the leads prior to installation.

- Someone had a great hint about dropping the leads into the holes from the bottom of the board and soldering them to the board first. This was really the enabler for handling the inside leads (between the crystals and RP4).

- I trimmed the leads in place to the correct length and used the "press it down with the flat end of a screwdriver" hint.

Next ... on to winding toroids!

Sunday, September 19, 2010

Middle of page 54

I've completed the section in which all the ICs are installed, along with some other odds and ends. The pile of un-installed components is noticeably smaller! Rather than post a "big picture" picture, I thought I'd post two detail shots.

Thursday, September 16, 2010

Lots of capacitors ...

|

Two fairly lengthy sessions and one shorter one resulted in my installing most of the front half of the RF board's diodes, transistors, and capacitors (all 68 of them!). |

The instructions for stuffing the diodes and transistors emphasized the need to minimize lead length by getting the components as close to the board as possible. For all of these, I soldered one lead, then reheated it while pushing in the component, then soldered the remained leads.

With some practice, I'm getting better at forming the leads for the tiniest capacitors. They really need to be bent out at 90° from the body of the component, and then 90° again. The trick is to get the two "down" bends the correct distance apart; I'm getting better at it with practice.

I also installed the two components in the vicinity of the thermistor board that I was concerned about. Q19 was not a problem at all; it's very close to the thermistor board, but did not touch. Installing C87 did require, as the instructions suggested, bending the thermistor board slightly in the direction of U6. I was able to install C87, but its body just touches one of the soldered connections on the bottom of the thermistor board. That should not be a problem electrically, but I put a little piece of electrical tape between them anyway (visible in the photo). If I ever do this again, I'll really try to minimize the amount of solder I use on the thermistor board.

Tuesday, September 14, 2010

Lots of resistors and the thermistor board

I've completed installation of lots of resistors and a few resistor networks on the front half of the RF board. The last several steps of this were devoted to construction and installation of a small daughter board, first introduced in 2003 (as far as I can tell), which replaces RP3 and provides temperature compensation to the PLL, thus greatly reducing warm-up drift.

It looks like getting C87 and RFC14 installed without shorting out to the back of the thermistor board will be difficult. Postings to the K2 forum all say "don't worry, it will all fit", but I think it may be necessary to put some electrical tape on the back of the thermistor board. It also looks like spacing for Q19 will be very tight. The instructions talk about checking to make sure that the thermistor board isn't shorting out to other components; this is not helpful at this point because the components haven't been installed yet!

For those keeping track ... just completed page 50.

Tuesday, September 7, 2010

K2 lives!

I ran through all the test procedures for this initial integration test, and everything worked fine. It was really fun to plug in headphones, hear and adjust the sidetone, plug in a keyer paddle and play with the built-in keyer, etc. The LCD display and bargraph both work/look terrific (all the scary directions about the LCD installation paid off!). I built and tested the frequency counter probe. And finally, I was happy to be able to make the AGC threshold adjustment to 3.80 volts without resorting to the "AGC Level Application Note."

Monday, September 6, 2010

Ready for first integration testing!

Remarkably few components were needed on the RF board to support the first chunk of "live" testing and alignment. I've included some low resolution pictures (didn't seem to warrant higher resolution, somehow) showing the RF board's connections to the outside world and front and back views of the K2 to date, ready to be powered up and tested.

I encountered the most difficult task to date, and that was getting the tilt stand installed. It extends about 1/2" past its mounting holes on the bottom panel and considerable force was required to compress it sufficiently to, with some luck and persistence, get its mounting screws to drop through the holes.

I also had the most satisfying moment to date, namely seeing how precisely all the connectors lined up and how smoothly the Front Panel and Control Boards plugged into the RF board.

I've decided that if there is a problem with construction, I don't want to know about it today. I plan to power it up tomorrow. Hopefully, there will be a happy post and picture to follow!

Saturday, September 4, 2010

Started the RF board

Friday, September 3, 2010

Front Panel Completed

I managed both an afternoon and evening construction session yesterday and finished the K2's front panel. The left-hand view shows the completed front panel board at the end of the afternoon session, while the right-hand view shows the completed front panel.

|

|

Despite the scariness of the instructions for the LCD backlight/diffuser and the LCD itself, construction was very straight-forward. The lesson again seems to be: "follow the instructions very carefully and all will be well." There was really nothing difficult about getting these components in correctly, including the "exactly 1/8 in." directive for placing the backlight assembly; using the provided spacers, you really couldn't go wrong. I did have the same moment's pause that other builder's reported on whether or not the LCD had a protective film on the back (and I actually just checked again that nowhere does it say to remove the backing from either side of the backlight assembly!).

Only glitch: the double-sided tape for holding the green bargraph filter in place crumbled when I tried to remove the second backing paper. Fortunately, I have double-sided tape around the house, which did the trick. Actually, I needed the double-sided tape to hold the two "self-adhesive rubber pads" in place as well.

Hint: used one of the LCD backlight spacers to position all the little knobs.

Next: sort out the all the parts for the RF board.

Wednesday, September 1, 2010

Front Panel Board - J1

Stuffed a few more parts today (R1-R5) and got U1 installed in its socket (took a fair amount of force to get it in, using thumbs on the front of the board ... it really is a good thing U1 is installed before the LCD assembly on the front!).

J1 is the 20-pin connector through which the RF board connects to the Front Panel board. It really needs to be mounted at right angles to the Front Panel board. What I did was hold J1 in temporarily with some tape and soldered only one end pin down. I then held the board and J1 in one hand, reheated the pin with the other hand, and settled J1 in flush with the board and perpendicular to it (I used a right angle on the end of a small metal ruler that I have to check). Then I soldered the other end pin, checked again, and then soldered the other 18 pins. (Oh, and I checked 4 times that I was installing it on the correct side of the board!).

Pics next time.

Tuesday, August 31, 2010

Page 25

The only noteworthy item today was the amount of force that it took to get J1 (the microphone jack), at the lower left corner of the board, properly seated.

In case you're wondering, assembly instructions start on page 14 and run through page 83.

Monday, August 30, 2010

Back at it ...

I was away for a week at Pinewoods, and am still recovering from a week's worth of not enough sleep. However, I managed to turn on the soldering iron this evening and stuffed a few components, including the 40 pin socket for U1 on the bottom side of the board.

Hope to make more progress tomorrow.

Thursday, August 19, 2010

Started the Front Panel

Wednesday, August 18, 2010

Control board done

I've completed construction of the control board, including scanning the bottom side of the board for shorts, cold solder joints, etc., as well as doing all the short testing recommended in the chart on the last page of the control board chapter.

The last two components to be mounted on the board are the two capacitors which comprise the keying shaping add-on to the board. It took quite a while to get C46 in particular situated on the board, so I thought it would be interesting to document how this came out:

|

The actual component for C46 was quite a bit larger than depicted in Figure 4-11, so the insulation bits needed to be a little shorter, and the leads needed to bent more squared off then in the figure.

Finally, I'm happy to report that I had installed RP2 correctly. Apparently, I'm the first person to ever write to Elecraft support after finding Figure 4-11 confusing WRT RP2 placement. Many thanks to Gary at Elecraft for helping me out with this today!

Tuesday, August 17, 2010

Control board almost finished

The other thing that held me up today was the pictorial of the underside of the board where these two capacitors are to be installed. If you have a look at the top right corner of the board, you can see the resistor network RP2 installed in its rectangular outline on the board. Just to the left is a round solder pad with the ambiguous marking "1". The pictorial of the underside of the board implies that that is where RP2's pin 1 should go. I think the marking on top of the board is most likely correct and the pictorial probably represents some older rev. of the board, but I wrote to Elecraft for clarification.

Sunday, August 15, 2010

Plugged in

Despite all the dire warnings in the manual, installing the off-board connecting plugs was really pretty straightforward. The only one which was slightly tricky was P1, since it would be possible to install it such that pins were not parallel to the board. However, once I got it seated correctly, I used an alligator clip to hold it in place and then soldered it in. The two-row plugs seated pretty much seated themselves.

P5 and P6 came with warnings about soldering each pin less than 3 seconds each, so as not to melt the plastic shells. I just made sure the soldering tip was really clean before I did the soldering and it really wasn't a problem. Maybe Elecraft can think about supplying plugs not so susceptible to heat damage.

Looks like one more stuffing session should finish up this board ... I'll post a picture when it's completed.

Saturday, August 14, 2010

Control Board Transistor, etc., Day

I had a good working session today, during which I installed all the transistors on the control board, as well some voltage regulators, crystals, and a socket for the PIC CPU for this board. Starting with this post, you can click on these small pictures to get the big view.

The other thing I did today was rig up a grounding clamp on a local cold water pipe, ran a piece of antenna wire down from it, and clipped my wrist grounding strap to the wire. Hopefully, this is an adequate grounding scheme. In any case, I kept the wrist strip on while handling all the transistors, etc., today.

Thursday, August 12, 2010

Control board capacitors are installed

|

I completed stuffing all the top side capacitors. |

You can see in the large photo that there is no C44; the board markings are apparently from a previous rev. of the kit. Also, the two apparently "leftover" capacitors are actually C45 and C46 which will be mounted on the bottom of the board as part of a key shaping circuit which has been added to the design.

Tuesday, August 10, 2010

Lots of solder ... not many components

Once again, I got a late start today. I installed all the resistor networks and a few other discrete components. The mounted component count didn't go up much today, but there were quite a few connections to be made. Rather than bending pins out to hold the resistor networks in place, I used short pieces of tape to keep them steady and flush to the board during soldering.

I have promised myself to stop working if I'm tired, so I didn't move on to the next chunk of component stuffing, despite today's low component count.

No pictures today. My next session will plant a forest of capacitors on the control board. When that's done, I'll probably post another picture.

Monday, August 9, 2010

And I'm Off ...

I finally managed to sit down at my bench last night to actually start construction. The K2 consists of three major board-level modules, the Control Board, the Front Panel Board, and the RF Board. The control board is the first module to be assembled and I thought I would document the beginning of construction with a few photos.

| Here are all the parts for the control board sorted out into an egg carton and a clear container that I picked up in someone's trash one day and just had to bring home . The second clear container (picked up on the same trash picking run) contains most of the parts from the K2's "Miscellaneous" bag (Click here for a bigger view of this). |

| And I couldn't resist (heh-heh) documenting my stuffing the first resistor of the construction project. |

Monday, July 26, 2010

At the starting gate ...

Once again, life has intervened and I haven't managed to start construction yet. However, I did, as noted previously, complete the inventory of the kit. Today, I cleaned up my workbench, got out all the tools, etc., for construction, laid everything out neatly, and took a picture to document where it is I'm starting from.

|

In the center of the picture is the box (not very big!) containing the inventoried K2 kit, with the construction/owner's manual in front of it. On top of the box are the hand tools I'll be using (pliers, diagonal cutters, etc.). To the right is my Weller soldering station and Panavise (a construction necessity, I think!). To the left is a DVM and the other absolute necessity, a sit-on-my-head magnifier. Completing my construction area are various part sorters and a component lead collector.

Really looking forward to actually starting construction.

Tuesday, July 20, 2010

The Beginning

I first noticed the Elecraft K2 when the product was introduced some 10 years ago. It got a really favorable review in the March, 2000, issue of QST. The reviewer at the time spoke highly of the kit-building experience, and raved about receiver performance.

Anyway, ten years later, having just passed a significant birthday, I decided to get myself a birthday present ... and a fairly lengthy construction project.

The K2 arrived last Wednesday, July 14 (having been delivered a day early by UPS!). I spent several hours this past weekend doing a complete inventory of the kit. All that was missing was 1 lock washer and 2 capacitors. The nice folks at the parts e-mail at Elecraft shipped them out the next business day.

I've owned a Weller soldering station for a number of years, but decided the new kit deserved new solder, and I ordered Kester 285 .025 diameter solder from one of the vendors mentioned on Elecraft's web site (and ordered some new desoldering braid and a desoldering pump while I was at it).

| Here's a picture from Elecraft's web site of what I will have when construction is completed. I've read that it takes an experienced builder something like 35 hours to build the K2. I'm planning that it will take me way longer than that ... and I thought it would be fun to keep track of my progress in word and pictures. |