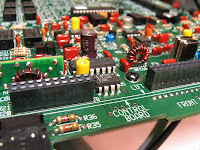

So, I took a look at the K2 forum, and found a variety of tips, none of which seemed like the answer to me, until I came across one response which referred to this awesome video (does require RealPlayer). Using an 800° tip on my Weller, the "scraping" step wasn't even necessary; I just held the tip of the iron there and stuffed solder in until ... voilà ... it "wet out" (to quote the guy in the video), and then I could just slide the tip and the solder down to the end of the lead. As the guy said, "solder is cheap" and I kept just stuffing it in there. Anyway, this worked like a charm; installing the RFCs, etc., has moved from the "scary" column to the "piece of cake" column.

By the way, the first RFC to be installed is RFC14, in that little space next to the thermistor daughter board. It was really no problem fitting it in; there again was "plenty" of room.